Orbis

December - July 2023

At Orbis, I was one of two full time mechanical engineers. I had to hit the ground running, learn quickly, and take ownership of many projects, which was a fantastic opportunity. I thrived in this fast paced environment, leading design on a planetary gearset retrofit project for an electric-converted McLaren MP4-12C, an integrated gearbox/motor/upright assembly, a hybrid battery mounting solution, and the optimization of an external brake rotor/”bell.”

I learned a lot at Orbis - one of the skills I was able to improve on the most was designing for manufacturing. I was in constant communication with Scott, the machinist and a co-founder of the company - I frequently asked him questions about how to make a part more machinable.

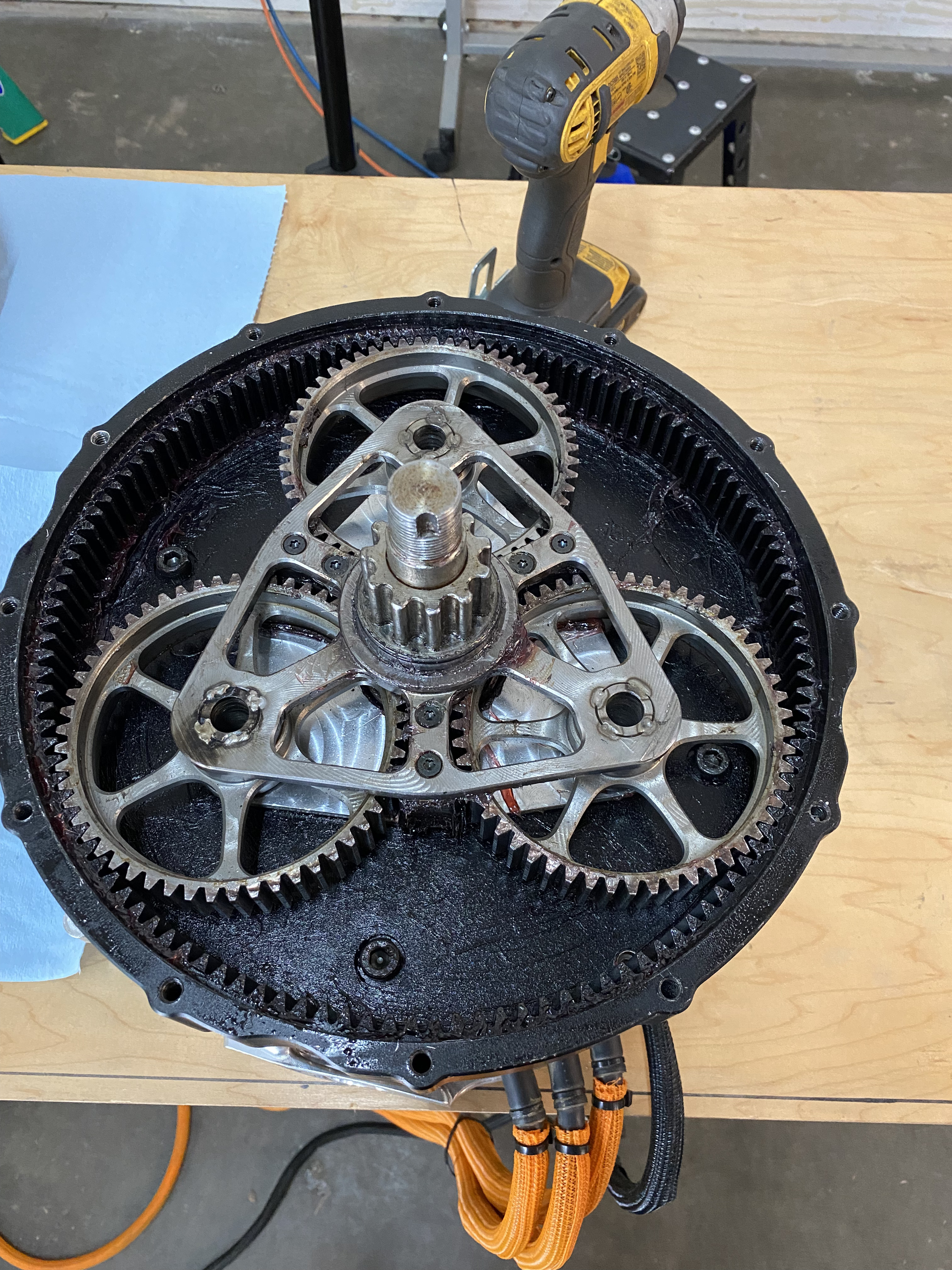

Planetary Gearset Retrofit

Requirements

- Reduce operating NVH

- Extreme timeline

- New gearset must fit within existing assembly and use existing splines

- Cost effective

My contributions

- Solely responsible for retrofit design and management

- Sourced gearset and worked directly

- with our machinist to make parts

- Tested NVH reduction with sound level meter

- Fitted to McLaren MP4-12C chassis

Design Process and Results

- New planetary gearset designed with helical gears

- Quotes showed that custom ring gears were too expensive and had long lead times

- Needed to pivot - a gearset from a junkyard automatic transmission was harvested and retrofitted to the assembly

- Testing with sound level meter proved significant NVH reduction

- Engineer sent from a major automaker from Wolfsburg approved the proof of concept’s NVH, resulting in a contract with the automaker

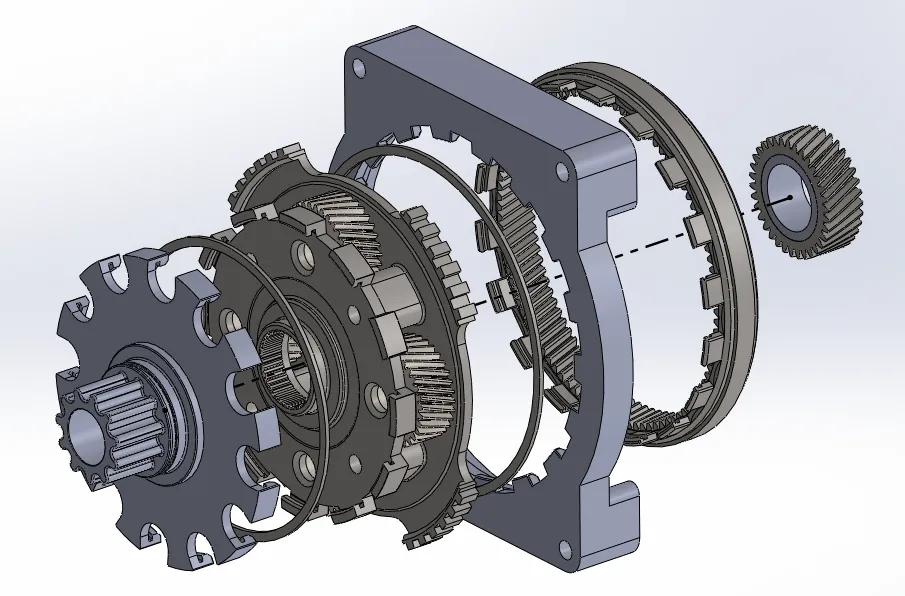

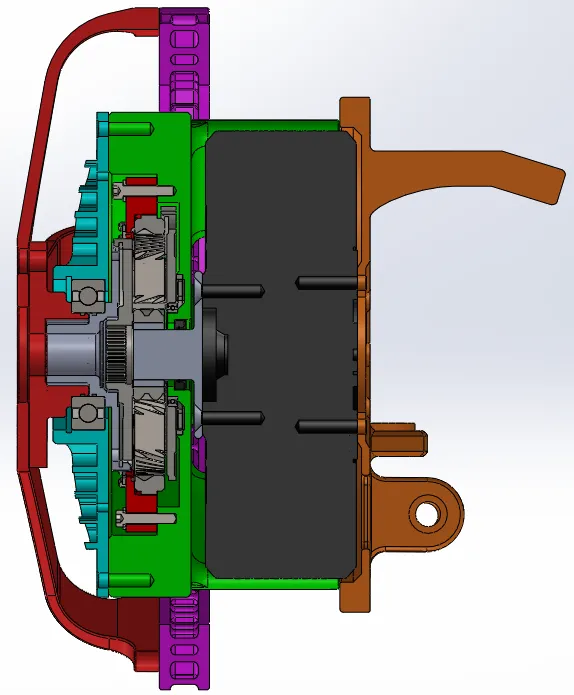

Gearbox, Motor, Brake, and Upright Assembly

Requirements

- Redesign previous assembly, keeping successful design elements and addressing failures

- Small form factor/stack height

- Lightweight

My contribtions

- Redesigned gearset stack - bearings, oiling, gearset selection

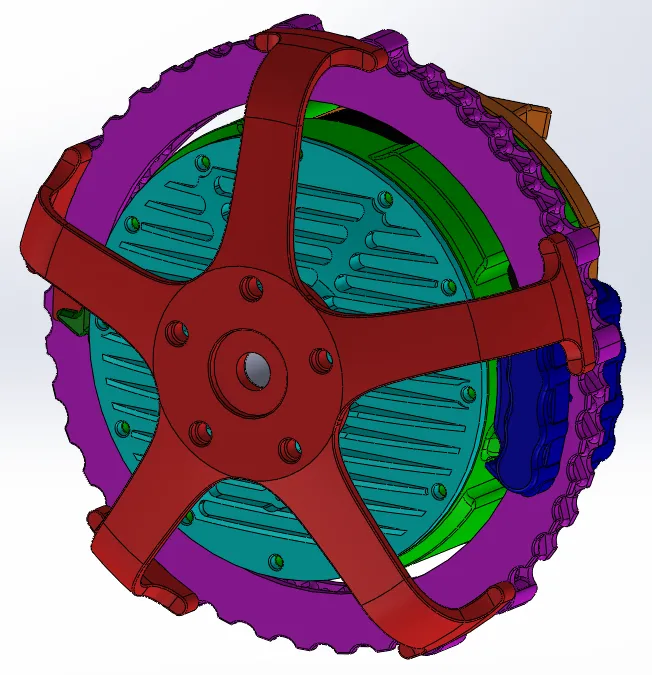

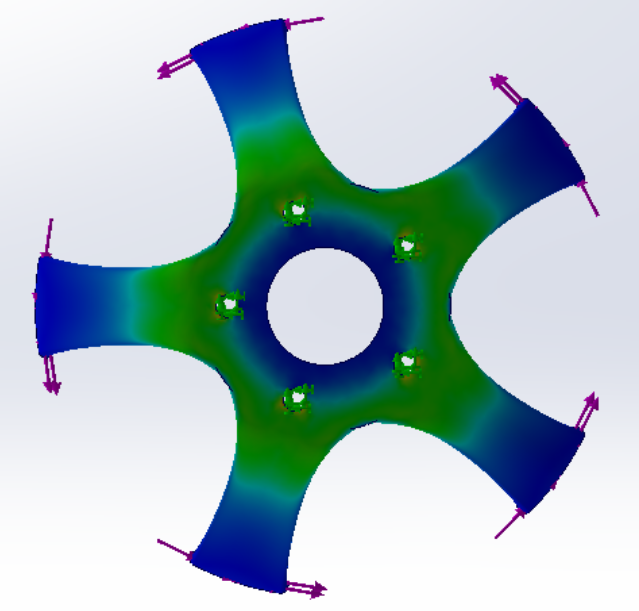

- Designed and optimized brake bell (red) with FEA

- Designed integrated upright (orange)

- Redesigned frustum that contains gearset (green)

- Work with machinist to make a printed model

Design Process

Address failures

- Previous bearing solution caused gears to take load from wheels and fail - redesigned to isolate gears from external forces

- New sealing solution designed to stop leaking

Reduce assembly’s stack height and weight

- McLaren MP4-12C upright integrated into motor mount

- Power dense axial flux motor used

- Lightweight brake bell, external rotor/internal caliper setup

- FEA used to optimized brake bell, reducing unsprung and rotating mass

External Brake Rotor/Bell

- Designed and worked closely with machinist to make “bell” to mount external brake rotor

- Mustang GT rotor lightweighted and adapted to function as an external rotor

- Tested at Greening to validate performance vs. original rotor

- Underperformed compared to original rotor, but was significantly lighter

Conclusions

- Promising results, but an equal mass comparison would be more valuable

- Brake rotor cooling optimization needed

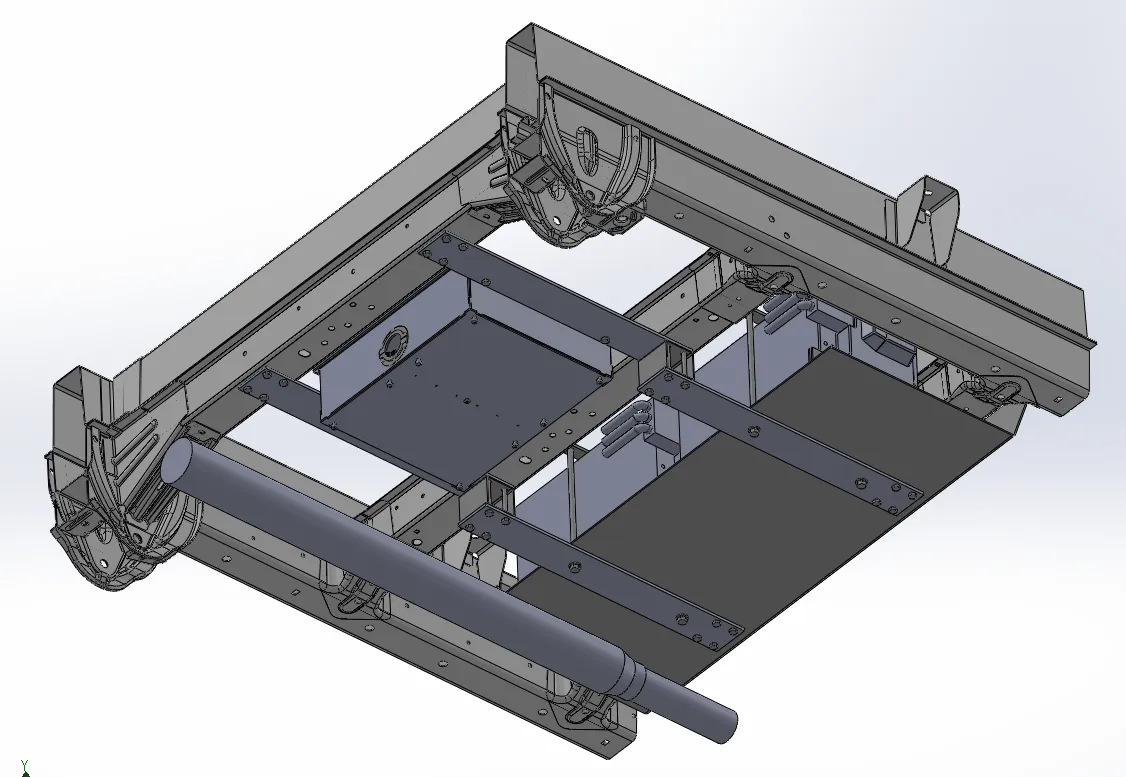

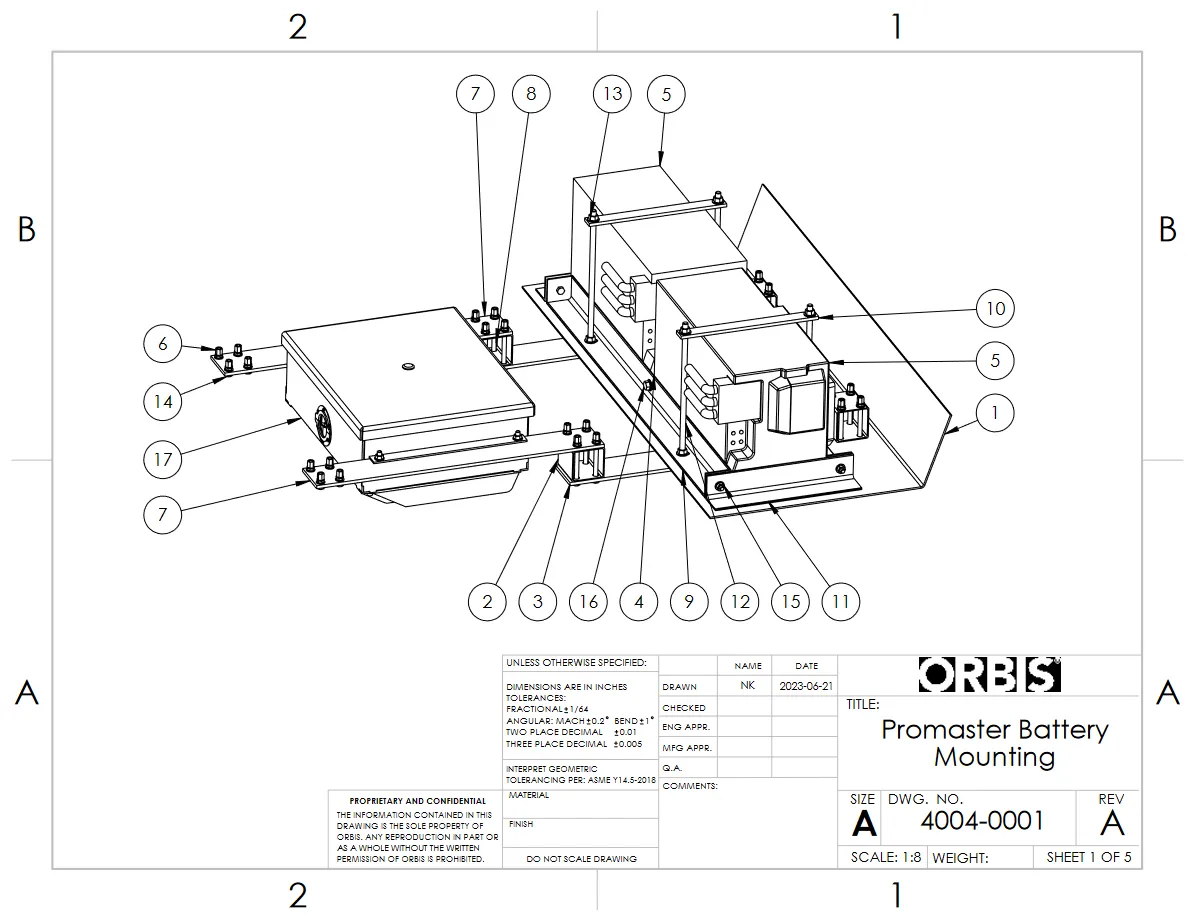

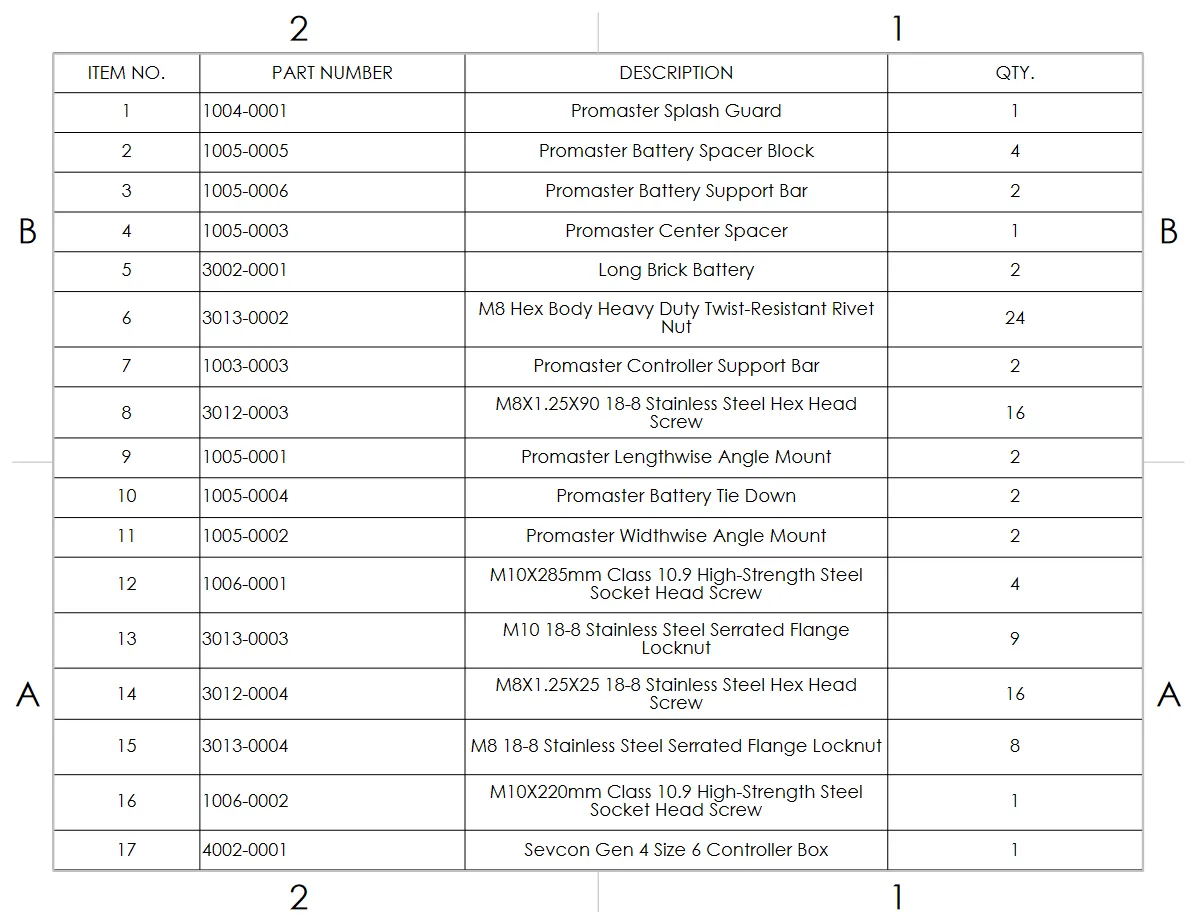

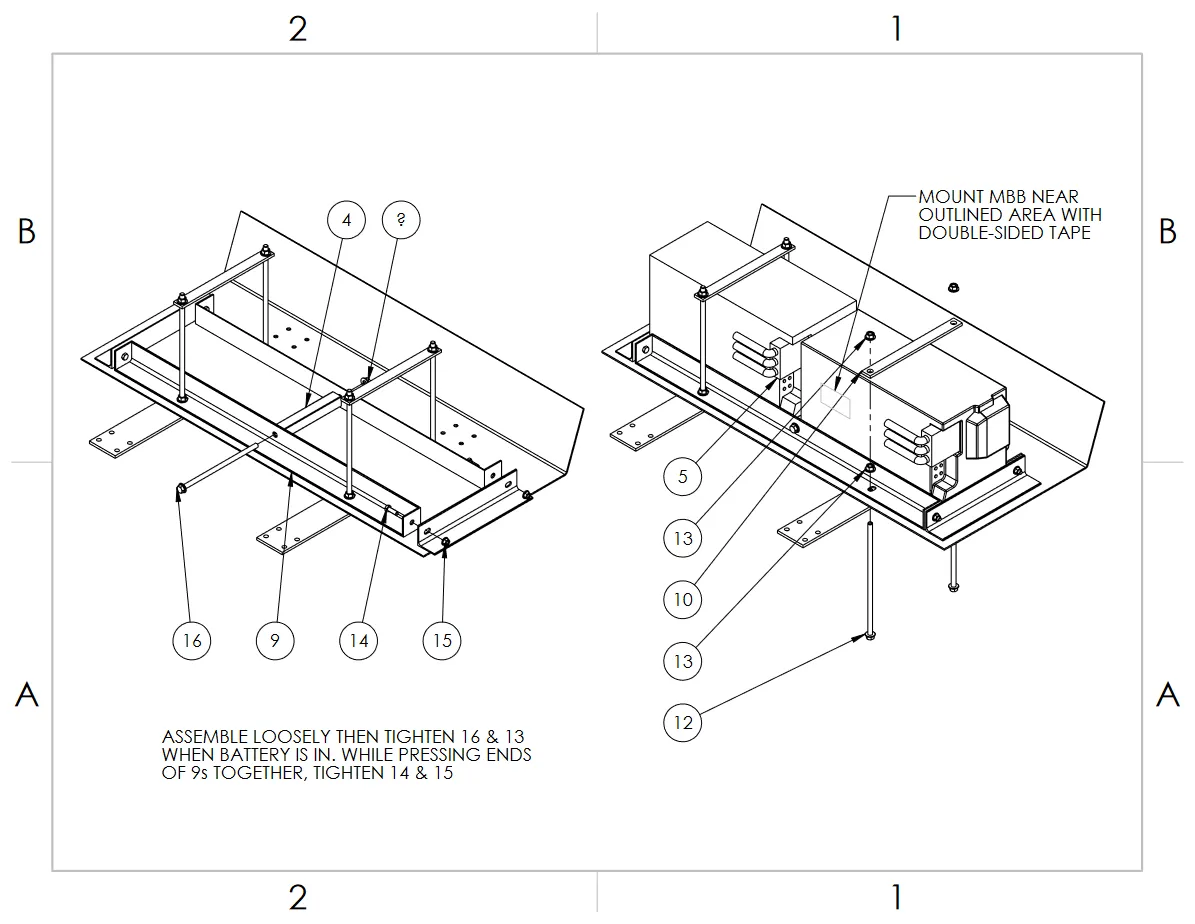

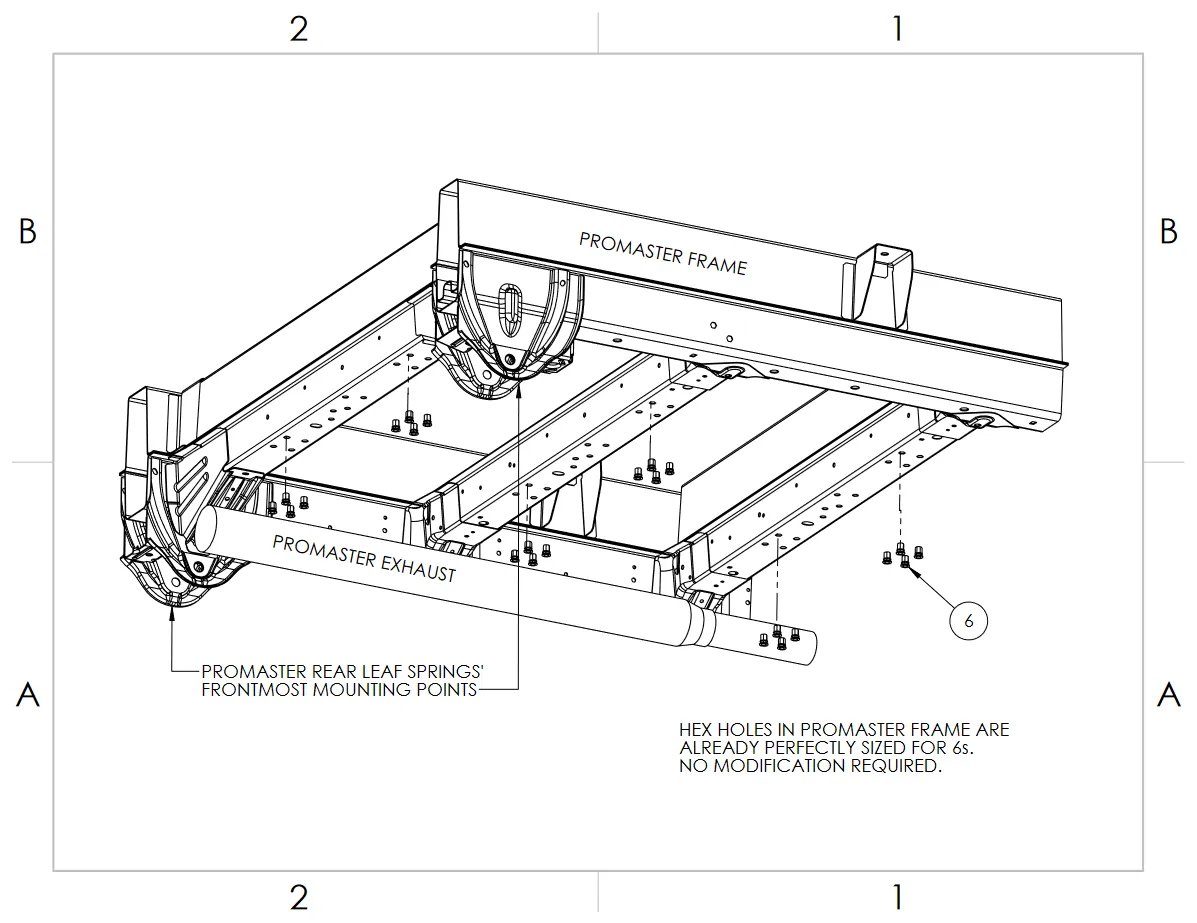

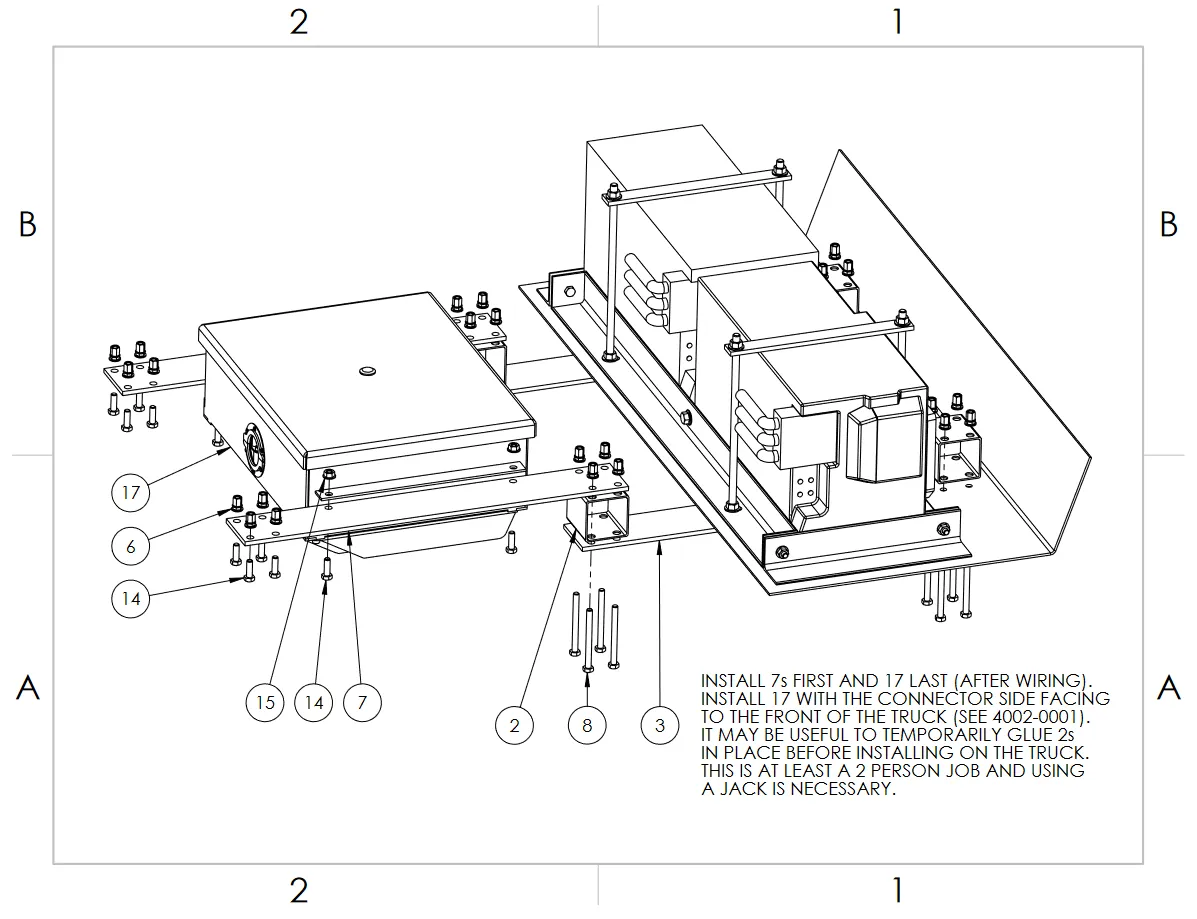

Promaster Van Hybrid Conversion Battery Mounting

Requirements

- Mount to Promaster box truck with minimal modification

- Less than 4 hour assembly time

- Easily installed and removed by non-specialized workers

- Corrosion resistant

Design

- Bolted to truck with 24 nut-serts in 6 locations - holes are already present, no modification needed

- Complete assembly and installation instructions made

- Corrosive resistant materials used for water resistant electronics enclosure and splash guard

- Sheet metal construction allows for easy prototyping and ramp up of production